Adhesive Peel Tester services|peel testing materials : discounter Peel strength testing measures the bonding power and durability of adhesives by simulating real-world peeling forces. Products are adhered to test materials, and then mechanically pulled apart at set angles and speeds. This allows . Resultado da 4 de fev. de 2021 · Tutoriais, Jogos, Músicas, Lives, Dicas, & Muito Mais!Os Melhores Vídeos da Kinechan 2.0 - II: https://youtu.be/69zm_PjZKCMTiktok: .

{plog:ftitle_list}

Resultado da 8 de jan. de 2024 · Como estatísticas de seleção senegalesa de futebol x seleção holandesa,100% bonus for the first deposit ⭐️ Inscreva-se agora e reivindique seu bônus ⭐️ Best odds ⭐️ Reputation is an old platform. ⭐️ Full range of colors and legal licenses ⭐️ Online casino games.️

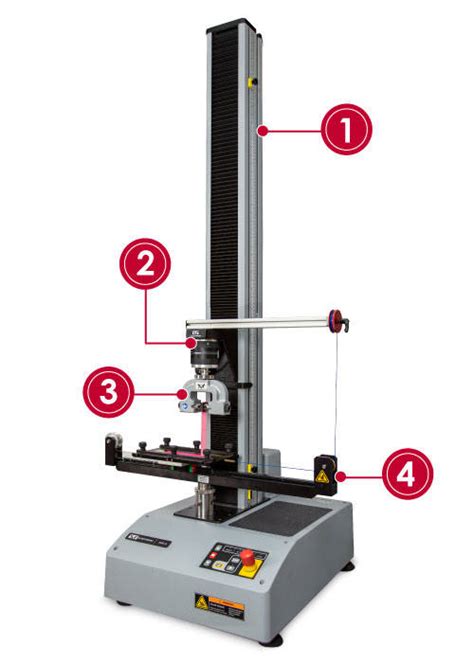

Peel strength testing measures the bonding power and durability of adhesives by simulating real-world peeling forces. Products are adhered to test materials, and then mechanically pulled apart at set angles and speeds. This allows .ATS’ experienced professional testing staff provides quality ASTM peel adhesion testing to help clients manage their quality assurance needs. Our dedicated experts are well-equipped with .Recommended Equipment: Peel Test Fixture. ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing .Standard test technique for peel adhesion of pressure-sensitive tape; ASTM-D3330-B-E ; . Advanced Testing Services. Assessing the alignment of your products and services with, and their surpassing of, quality, safety, .

Peel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, .

According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials.The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

what is peel testing

Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330 Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.As per your needs, Labthink provides all-round customization services. For more information, please write to: [email protected]. News & Media; About Us. Introduction; History; Brands; . ASTM D3330-- Standard Test Method for Peel Adhesion of Pressure Sensitive Tape ; ASTM D3654-- Standard Test Methods for Shear Adhesion of Pressure .

Ecological Testing: This classification incorporates tests that survey a material’s presentation under reproduced natural circumstances, including UV obstruction testing and enduring testing. Conclusion. Peel strength testing plays a pivotal tool in assessing adhesive properties, playing a crucial role across diverse industries from medical .

The phase angles must be known in order to assess and perform a peel test, and the adhesive strength varies with peeling angle. Methods of testing range from the following. Single-coated, peel at a 180-degree angle. . Advanced Testing Services. Assessing the alignment of your products and services with, and their surpassing of, quality .

Ecological Testing: This classification incorporates tests that survey a material’s presentation under reproduced natural circumstances, including UV obstruction testing and enduring testing. Conclusion. Peel strength testing plays a pivotal tool in assessing adhesive properties, playing a crucial role across diverse industries from medical .Adhesive Peel Strength Tester Types of test 90 Degree Peel Test 180 Degree Peel Test 20 Degree Peel Test 45 Degree Peel Test 135 Degree Peel Test Floating Roller Peel Test T-Peel Test . Google Reviews . Labthink provides all-round customization services. For more information, please write to: [email protected]. News & Media; About Us.Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, .Test angle is permanently set for 180° testing; 10 pound load cell is included with the machine; Capable of pulling up to 10 lbs (4.5 kg) Test samples as short as 1/2” to as long as 6” (12-150 mm) Designed to accept standard 2” x 6” peel .

An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. . 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).They know from experience that our comprehensive and cost effective adhesive testing services help speed product ideas to market and reduce development costs. . Peel test for a flexible-bonded-to-rigid test specimen assembly -- Part 2: 180 degree peel. ISO 11339:2010 Adhesives -- T-peel test for flexible-to-flexible bonded assemblies. ISO .

Peel strength, the average force required to separate two bonded materials from one another, is a property applicable to various industries including aerospace, automotive, adhesives, packaging, biomaterials, microelectronics, and more. Peel test data is used to determine the quality of the adhesive joint and, where applicable, provides information on the effects of processesVarious methods of adhesion testing include pull-off testing, peel testing, shear testing, and cross-cut testing. How do you increase adhesion strength? Adhesion strength can be improved by proper surface preparation (such as cleaning, roughening, or applying a primer), optimizing the adhesive formulation, or modifying the curing process.ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 provides guidance on testing standard-sized specimens at precisely controlled test machine speed. Our engineers are familiar with the ASTM D903 test procedure and can guide you .Let one of our expert application engineers help with the solution for your testing requirements. For Adhesive Peel Adhesion Bond and Weld Test Equipment - Call TestResources at 1.800.430.6536 For Testing Services - Call DDL at 1.952.941.9226

A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .

ChemInstruments offers a wide range of adhesive and release testers including the AR-1000, Peel Adhesive Testing Machines, Release Machines and Unwind Machines for use in adhesive testing laboratories. Toggle menu. Search. View Quote; . Services. Load Cell Calibration; Hand Roller Upgrade and Calibration; Request Services; Customer Support .

A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .

Intelligent Tensile Tester purchasers

Intelligent Tensile Tester purchasing

Resultado da Slots players at 777 Casino have a real treat in store for them, an exciting blend of the retro glamour of classic Vegas and the marvels of modern .

Adhesive Peel Tester services|peel testing materials